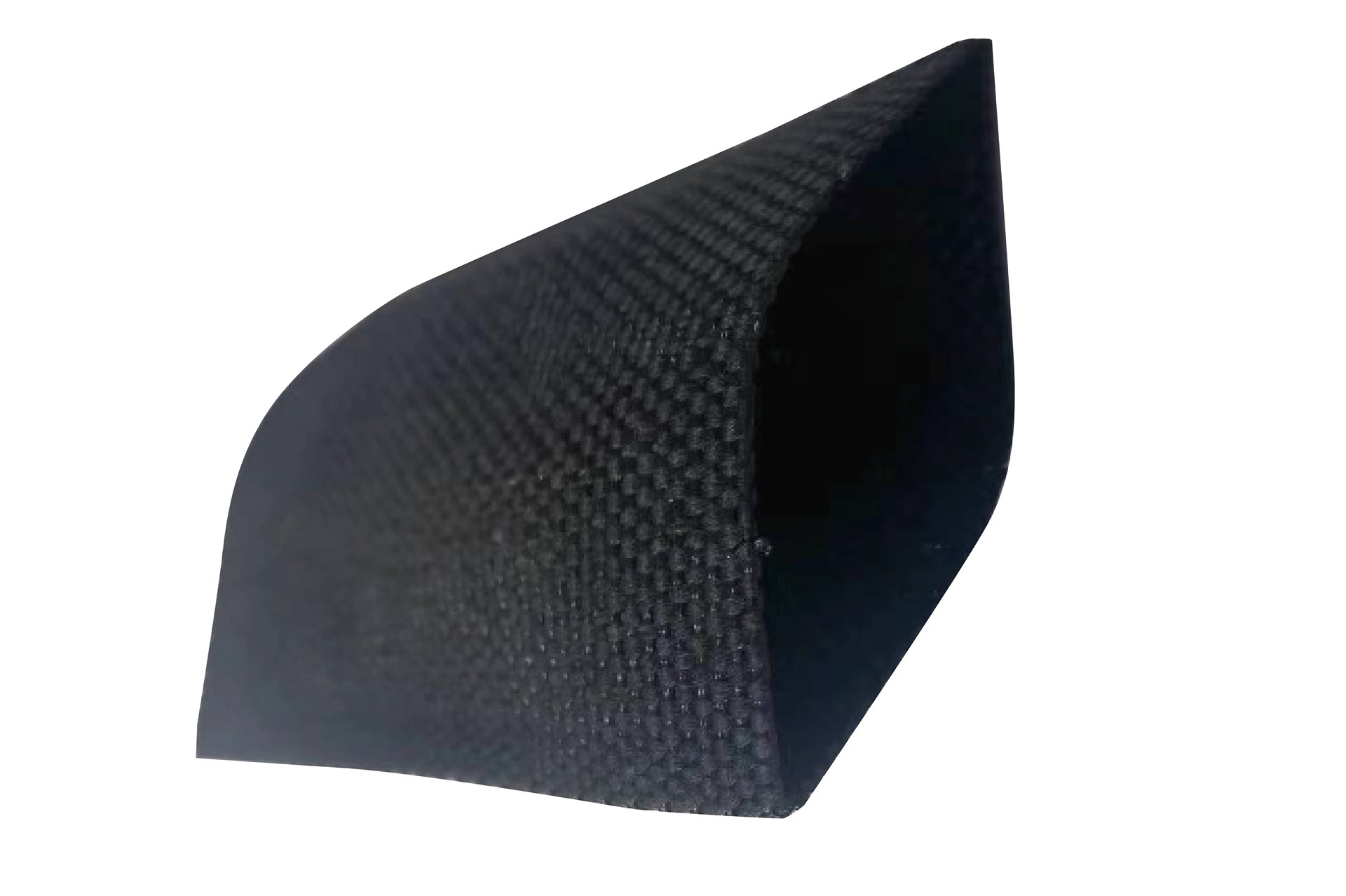

heat shrink sleeve

Engineered composite braid comprising high-tenacity polyester multifilament and ultra-wear-resistant polyester multifilament yarns, integrated through proprietary thermofusion bonding technology.

Provide excellent wear resistance for rubber pipes and other pipelines

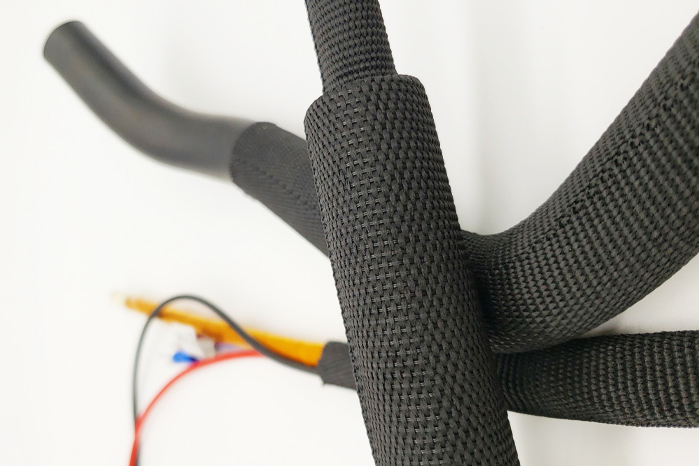

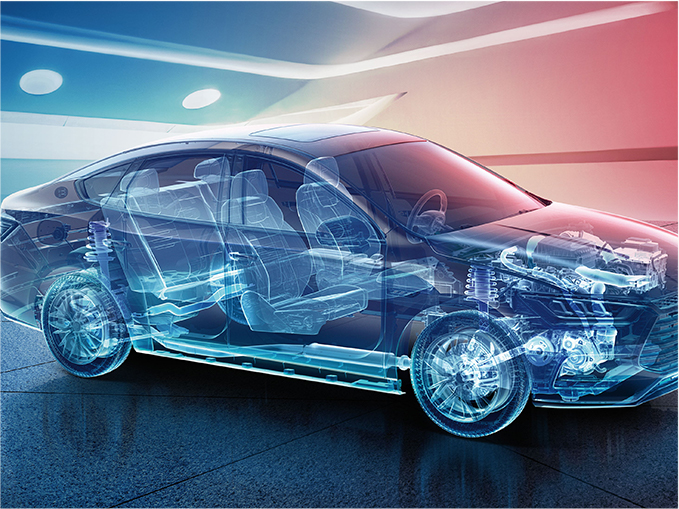

Product Application

Features

Send a Message

If you have any needs, please feel free to contact us by leaving a message or sending an email. We will strive to respond to you as promptly as possible.

Required fields are marked.

- Application

- Features

- To Top